1mm thick special EVA Flooring Acoustic Underlay is designed for any vinyl flooring. 1mm denser EVA underlayment reduces floor noise by providing excellent sound absorption properties. In addition to sound absorption, it also serves as a superb moisture barrier. This high-density foam is suitable for use with floating WPC + Rigid Core LVT floors.

Specification

| EVA Foam Underlay Material For Vinyl flooring | |

| Foam Type | Ethylene-Vinyl Acetate Foam |

| Available Density | 110kgs/m3 |

| Thickness | 1-3mm or customized |

| Coating process | No Film.PE film, silver film, aluminum foil or others |

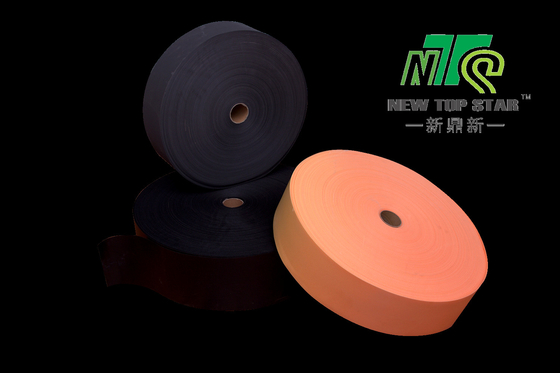

| Color | Black, blue, green, orange or others |

| Width | 1-1.5m,Max 1.8meter |

| Length | 300-400m or customized |

| Feature | High density; smooth; comfortable; tough; low water absorption |

| Application: |

Being used in PVC, WPC flooring, construction, roof, wall insulation; Heat insulation material for automotive, sports &leisure industry so on. |

| Function: |

· Closed cell structure · Long lasting insulation material · Excellent thermal insulation · Acoustic noise reduction · Constant energy saving · Flame retardant protection |

Embossing means create a raised pattern on a foam passed between embossed rollers at high temperatures and pressures. For the purpose of meeting customer’s requirements by heat embossing closed cell crosslinked PE foam. Especially for sports and leisure industry, such as yoga mattress, cross-fitness mattress.

The embossed roller is engraved with a pattern that is transferred to foam under heat and pressure. The embossing process increases the density of the foam cells at the surface. This changes the acoustical signature to aid in better low frequency absorption and provides a unique aesthetic look.

Top Star Factory offers the best solution for polyethylene foam production, We supply PE foam in rolls, length of each roll can be customized to meet customer's requirement. The PE foam product can also be provided on the sheet as a request.Here support foam die- Cutting, Lamination Adhesive, Sheeting, Perforating & Skiving.All the service are focused on quality of products and satisfied our customer.

A variety of THICKNESS and WIDTH can be Customized:

DENSITY: :26-300kg/m3 (kilogramme per metric cube).

THICKNESS, single layer sheeting of 0.5-15mm, and also laminating multiple layers of sheets up to 80mm.

WIDTH, produced in roll form of 1.0M - 1.8M, depending on foam density and thickness.

FORM of the finished product are converted into roll, sheet, laminated, die-cut and 3D glued, according to client's request.

1. Why would I prefer to use cross-linked foam?

Cross-linking can improve physical properties of the foam, including water-proof, tensile strength, elongation,heat stability and so on.

2. What is difference between XPE and IXPE Foam?

XPE is chemical cross-linked, IXPE is physical type, which’s surface is more smooth and cell size is smaller than XPE. Also thickness evenness is better than XPE.

3. Why would I prefer to use a foam made with polypropylene (PP) instead of polyethylene (PE)?

PP offers greater heat stability and strength at elevated temperatures than does PE. PP is preferred for today's forming and injection processes, which are used to mold automotive interior panels, including door panels and instrument panels.

4. What types of floor covering are compatible with your underlayment?

We offer acoustic underlayment for laminate, engineered, wood. LVT, SPC, WPC, Pls contact us for more details.

5. Do you have any special functions foam?

Yes, we can produce anti-bacterial type, anti-slip type, flame retardant type, anti-static type, conductive and others.

6. What thickness, width, and colors do you offer?

Our thickness range is from about 0.02 mm to 8 mm in single layer and more than 65mm after lamination.

The max. width we produce is 1700mm depends on different spec. Standard black, white,, gray, orange, green,and custom colors are available.